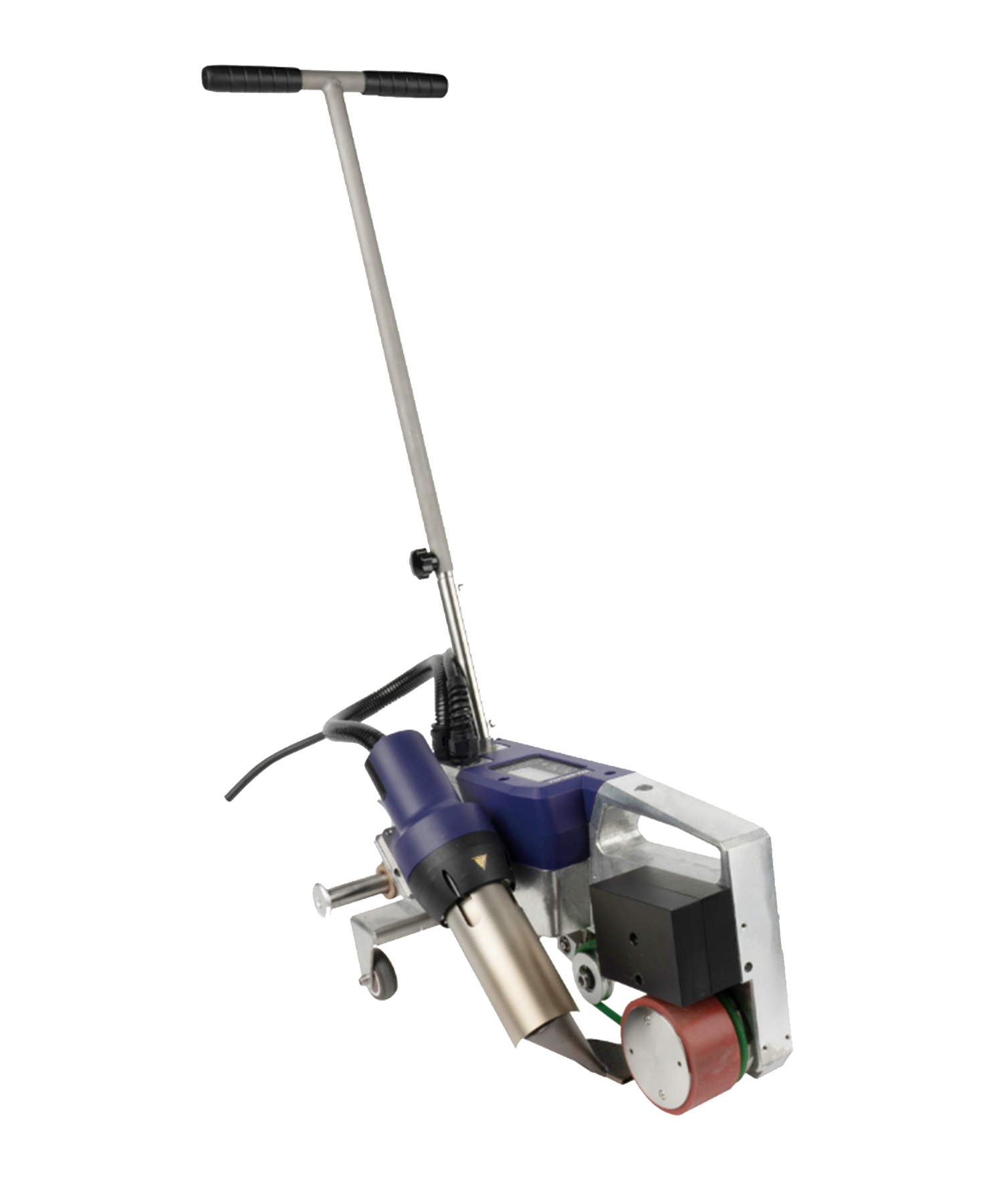

In the fields of electronic repair, industrial production, and DIY, hot air guns have become essential tools. In 2025, with technological advancements, a large number of new products will emerge in the market, but the quality will vary greatly, making it difficult for consumers to make choices. This article will analyze the 5 most critical core parameters when choosing a hot air gun, helping you accurately avoid pitfalls and select the truly suitable professional equipment. We will provide you with the latest and most professional purchasing advice from the dimensions of power performance, temperature control accuracy, air volume performance, safety and durability, and accessory expandability. Whether you are an electronic engineer, industrial technician, or handicraft enthusiast, this guide can help you make wise choices among numerous products, avoid wasting money on unsuitable tools, and ensure that every investment you make is worth it.

Power and heating rate: fundamental performance indicators

The power parameter directly determines the core performance of the hot air gun. By 2025, mainstream hot air gun products in the market can be divided into three clear grades based on power differences: entry-level models ranging from 500-800W are suitable for occasional household users; The mid-range models of 800-1200W meet daily maintenance needs; The professional grade models of 1200-2000W are designed for industrial applications.

The power selection needs to adhere to an important principle: power is directly proportional to the heating rate, but also positively correlated with energy consumption. Taking actual test data as an example, the high-performance 1800W model can soar to a working temperature of 600 ℃ in just 30 seconds, while the ordinary 800W model requires more than 2 minutes of preheating time. The difference in heating rate will directly affect the overall work efficiency in continuous operation scenarios.

The most noteworthy technological breakthrough in 2025 is the intelligent power management system. Industry leaders such as Kuaike and Bosch have launched flagship products equipped with advanced "intelligent frequency reduction" technology. The system can monitor the working temperature in real time and automatically adjust the power output after reaching the set value, achieving a perfect balance between rapid heating and energy-saving operation.

When making a purchase, special attention should be paid to the following key points:

Be wary of the phenomenon of power false labeling in low-priced products, and it is recommended to choose branded products with authoritative certification

Choose the appropriate power based on usage frequency: around 800W is recommended for home use, and 1200W is recommended for professional maintenance starting from

Focus on third-party measured data rather than simply trusting the manufacturer's nominal parameters

Consider the power supply conditions of the work environment to ensure that the power supply system can support the power requirements of the equipment

Pay attention to the balance between power and body weight, as excessive power may affect operational convenience

Temperature control accuracy: the watershed between professional and amateur

The accuracy of temperature control is a key indicator for evaluating the professionalism of a hot air gun. By 2025, high-end models will generally adopt PID intelligent temperature control systems, combined with high-precision K-type thermocouple sensors, which can achieve precise temperature control of ± 1 ℃, fully meeting the requirements of precision operations.

Temperature selection guide for different application scenarios:

It is recommended to use the temperature range of 50-450 ℃ for precision electronic maintenance

Recommended temperature range for plastic welding operations: 200-500 ℃

Industrial grade applications can support up to 650 ℃ high temperature

Development status of temperature control display technology:

Traditional mechanical knobs: easy to operate but low precision (± 20 ℃)

Digital display screen: temperature visualization, accuracy improved to ± 5 ℃

Intelligent digital display system: professional grade accuracy (± 1 ℃), supporting temperature memory function

Precautions for purchasing:

Prioritize models with temperature display function to avoid blind operation

Confirm the use of K-type thermocouple sensors to ensure the accuracy of temperature feedback

Test temperature recovery speed, high-quality models can quickly recover after cooling down

Check temperature stability, and ensure that fluctuations during continuous operation do not exceed the nominal value

Pay attention to the temperature adjustment step value. Models with a unit of 1 ℃ are more accurate

Special reminder: For precision operations such as SMD component soldering, it is recommended to choose high-end models that support temperature calibration function and regularly perform temperature calibration to ensure work accuracy.

Wind volume and pressure: key parameters for precise operation

The performance of air volume and pressure directly affects the working effect of the hot air gun, and the technological progress of mainstream models in this regard will be significant by 2025. The airflow range of modern hot air guns has been expanded to 50-800L/min to meet the needs of different scenarios.

Suggestions for selecting professional air volume:

Precision electronic maintenance: 50-150L/min (to avoid component displacement)

• Regular DIY homework: 150-300L/min (balancing efficiency and accuracy)

Industrial grade application: above 300L/min (rapid large-area heating)

Core technology breakthroughs by 2025:

Double vortex duct design: By using spiral airflow, the heat distribution is more uniform, and the thermal efficiency is increased by 30%

Stepless variable speed regulation: achieve precise adjustment of 10L/min to meet different operational needs

Silent technology: using magnetic levitation fan, the working noise is controlled below 55dB

Precautions for purchasing:

Prioritize selecting models with multiple adjustable gears or infinite speed regulation

Measure the linearity of air volume to ensure precise adjustment

Check the compatibility of the air nozzle to ensure that the accessories are replaceable

Pay attention to the maximum wind pressure index, which affects penetration power

Choose high-end models with air volume memory function

Special Reminder: For precision operations such as BGA rework, it is recommended to choose professional models with "Breeze Mode" (<100L/min) and use them with dedicated focusing nozzles to achieve the best operational results.

Safety and durability: the foundation of professional tools

In 2025, the safety performance of hot air guns will undergo a significant upgrade. The latest EN60745 standard from the European Union requires all products to be equipped with a triple protection system: intelligent overheating protection, current overload protection, and dual accidental start protection, providing users with comprehensive safety protection.

Analysis of core durability indicators:

Heating element innovation: The third-generation ceramic heating element has a lifespan of 3000 hours, which is 5 times longer than traditional resistance wires

Shell material: Made of UL94 V0 flame-retardant composite material, with a melting point of up to 650 ℃

Wire standard: 3-meter-long high-temperature resistant silicone wire (300 ℃ resistant) has become a standard configuration for high-end models

Cutting edge security technology:

Intelligent sleep mode: idle for 5 minutes, automatically entering low-temperature standby mode

Double grip insulation: The surface temperature is always controlled below 45 ℃

Emergency rapid cooling: cool down to safe temperature within 30 seconds after shutdown

Purchase warning:

① Identify international safety certification marks such as CE/UL

② Tested handle temperature, continuous operation should not be hot to the touch

③ Check the flexibility of the wire and the firmness of the plug

④ Confirm the response speed of overheating protection (high-quality models ≤ 3 seconds)

⑤ Prioritize selecting models with replaceable heating element designs

Professional advice: Industrial users should pay extra attention to the IP protection level and choose at least IP20 standard models to prevent dust and splashes.

Accessories and Scalability: Extended Value for Professional Applications

In 2025, the accessories ecosystem of high-end hot air guns will undergo a revolutionary upgrade, and modular design will become the mainstream standard in the industry. Each brand has launched a patented quick release system, which enables nozzle replacement to be completed in 1 second, greatly improving work efficiency.

Professional level accessory configuration plan:

• Basic package: standard round/flat/focusing three nozzles

• Electronic repair kit: includes anti-static nozzle (<10 Ω resistance value) and BGA dedicated fan cover

Industrial kit: including wide diffusion nozzle and high-temperature resistant ceramic air nozzle

Annual Innovative Accessory Technology:

Intelligent temperature control nozzle: built-in temperature sensor, real-time display of working surface temperature

Magnetic quick change system: supports one handed operation, positioning accuracy ± 0.1mm

Multi functional bracket: supports 360 ° rotation adjustment, with temperature memory function

Precautions for purchasing:

① Confirm the standardization level of the interface (it is recommended to choose a universal 1/4 inch thread)

② Priority should be given to selecting nozzles made of 304 stainless steel material (with a temperature resistance of over 800 ℃)

③ Inspect the accessory supply system (mainstream brands need to ensure a 5-year accessory supply)

④ Pay attention to the cost-effectiveness of accessory packages (the single purchase price should not exceed 30% of the set price)

⑤ Verify the interchangeability of accessories (cross brand compatibility testing)

Special Reminder: Professional users are advised to choose an open platform that supports customization of 3D printing accessories, and can design specialized accessories according to their special needs.

I deeply understand the saying 'To do a good job, one must first sharpen their tools'. I remember when I first entered the industry, I bought a miscellaneous brand hot air gun for the sake of cheapness. However, during the repair of a high-end motherboard, the temperature went out of control and the chip was directly burned, resulting in heavy losses. This lesson made me understand that professional tools are worth investing in professionally.

After years of user experience, I have summarized the following purchasing experience: first, honestly evaluate your own usage needs. For precision electronic repairs like mine, it is necessary to choose professional models with temperature control accuracy of ± 1 ℃. And for occasional DIY friends, mid-range models are completely sufficient.

In terms of budget, I suggest professional users directly consider models above 2000 yuan. Remember, good tools are partners in making money, not just expenses.

I strongly recommend that if conditions permit, it is necessary to conduct on-site trials. Only through personal experience can we determine whether parameters such as hand feel, weight, and wind noise are suitable. Just like when I tried out 5 models before deciding that this one is the most suitable for long-term holding.

After sales service is equally crucial. My hot air gun experienced a temperature control malfunction last year, and the brand's quick response and free repair helped me avoid work stoppage. So it is important to choose a brand with a well-established after-sales system.

Finally, I would like to remind everyone to focus on future needs. I am now very fortunate to have chosen a model with a rich accessory system. With the expansion of our business, we only need to purchase specialized nozzles to meet new maintenance needs.

The hot air gun market in 2025 is indeed dazzling, but as long as you grasp these core elements, you will definitely find the most suitable "capable assistant" for yourself. After all, for those of us who rely on craftsmanship to make a living, good tools are the most worthwhile investment.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.