1. Heating Element Technology Evolution

1.1 Metal Heating Wire Limitations

Traditional nickel-chromium (NiCr) heating elements face three fundamental constraints:

Power Density

Limited to 5W/cm², requiring longer heating elements that increase tool size and weight.

Thermal Response

30-60 second warm-up time from cold start to operating temperature (400°C).

Service Life

Rapid oxidation above 600°C reduces lifespan to approximately 500 hours.

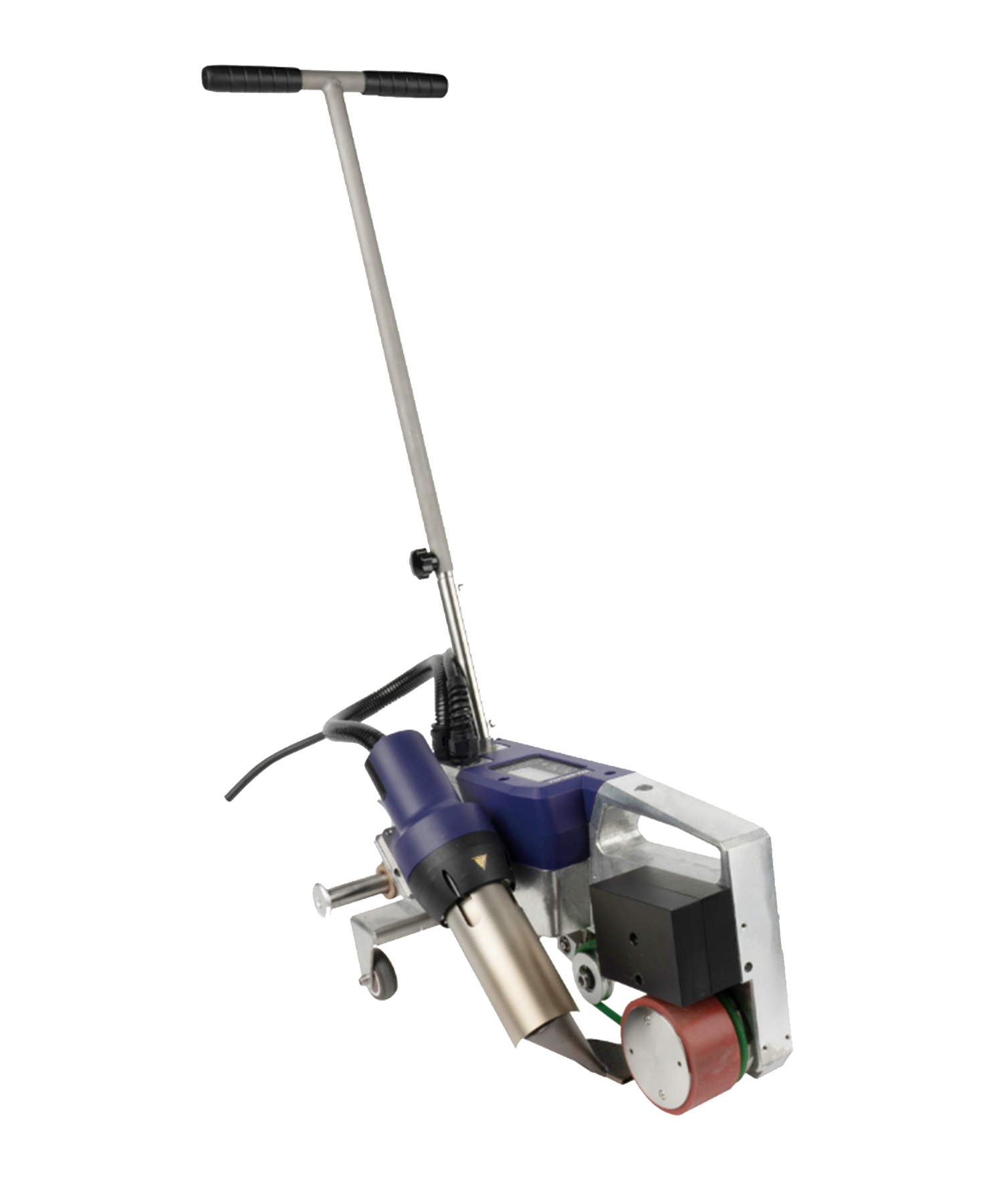

Figure 1: Microstructure comparison between traditional metal and modern ceramic heating elements

1.2 Ceramic Heating Breakthroughs

Positive Temperature Coefficient (PTC) ceramic elements revolutionized hot air gun performance:

| Parameter | Metal Element | Ceramic Element |

|---|---|---|

| Power Density | 5W/cm² | 15-20W/cm² |

| Warm-up Time (to 400°C) | 30-60s | 2.8-3.5s |

| Service Life | 500 hours | 3000-5000 hours |

| Self-Regulating | No | Yes (650°C auto-limit) |

2. Precision Airflow Control Systems

2.1 Aerodynamic Engineering

Professional-grade hot air guns implement advanced fluid dynamics principles:

Venturi Intake

Three-stage filtration (≥95% efficiency at 20μm) with optimized 15° taper angle

Spiral Heating Chamber

Helical vanes create turbulent flow for 87% thermal transfer efficiency

Nozzle Dynamics

Boundary layer control maintains laminar flow up to 15cm from outlet

2.2 Motor Technology Comparison

| Feature | Brushed Motor | Brushless Motor |

|---|---|---|

| Noise Level | 68±3dB | 58±2dB |

| Lifespan | 800 hours | 4000+ hours |

| Airflow Stability | ±12% | ±4% |

| Energy Efficiency | 1.2W/(L/min) | 0.8W/(L/min) |

Key Takeaways for Professionals

1. For electronics repair: Prioritize ceramic heating elements with PID control (e.g., Quick 303D+)

2. Industrial applications: Require brushless motor systems with ≥4000h lifespan (e.g., Hakko FR-801B)

3. Always verify temperature uniformity (±10℃ across nozzle) and airflow stability (±5% variance)

4. Consider future-proof features like IoT connectivity and programmable thermal profiles

About the Author

The Technical Tools Review Team consists of certified electronics engineers with combined 50+ years of field experience. Our testing methodology follows IEC 60745 and UL 60745 standards, using calibrated Fluke thermal imaging equipment and laboratory-grade airflow measurement devices.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.