A high-quality hot air gun is one of the most versatile tools in any workshop. From heat-shrink tubing and vinyl wrap to paint stripping, plastic bending, and adhesive removal, learn why an adjustable, well-built heat gun saves time, improves results, and pays for itself quickly.

The Unsung Hero of Making and Repair

If you’re building, fixing, customizing, or prototyping, chances are you’ve wished for a safe, controllable source of high heat. That’s exactly what a hot air gun delivers. Unlike open flames or bulky ovens, a heat gun focuses heated airflow with precision—letting you soften, shrink, cure, or release materials exactly where you need to. Whether you’re a DIY hobbyist, an auto-wrap specialist, or an electronics technician, a dependable unit becomes the tool you reach for daily.

The magic is control. Dial in temperature and airflow, choose a specialty nozzle, and you can gently set epoxy, cleanly remove decals, bend acrylic with smooth radii, or reflow solder on stubborn joints. High-quality models maintain stable output, so your results are repeatable—not a guessing game.

Top Use Cases That Pay Off Fast

- Electronics & Wiring: Heat-shrink tubing, conformal coatings, gentle connector loosening, and flux activation without scorching boards.

- Automotive & Wraps: Vinyl wrapping, badge/decal removal, adhesive softening, PPF edge setting, and interior trim repairs.

- Wood & Finishing: Paint/varnish stripping, raised-grain finishing, and targeted drying of fillers or stains.

- Plastics & Prototyping: Bending acrylic or PVC, plastic welding with reducer nozzles, smoothing 3D prints, and forming kydex.

- Home Repairs: Loosening old caulk, defrosting frozen pipes safely, removing stuck labels, and lifting dented bumper edges.

- Crafts & Making: Candle making, embossing powders, resin bubble removal, and leather working (edge burnishing aids).

Heat Ranges & What They’re Good For

Use this quick guide to match temperature to task:

| Temperature (°C) | Common Uses | Notes |

|---|---|---|

| 50–150 | Drying, label removal, gentle heat-shrink | Keep gun moving; avoid hot spots |

| 150–300 | Heat-shrink tubing, vinyl wrap, soft adhesives | Medium airflow for control |

| 300–500 | Paint stripping, plastic bending, light solder | Ventilation and gloves recommended |

| 500–650+ | Plastic welding, stubborn fasteners, heavy stripping | Experienced users only—high heat risk |

Why “High-Quality” Matters

1) Accurate, Stable Temperature: Cheap guns drift. Premium models use closed-loop control to hold set temperatures even as ambient conditions change.

2) Adjustable Airflow: Control spread and intensity. Low airflow = precision; high airflow = coverage.

3) Interchangeable Nozzles: Concentrators, reducer nozzles, reflector nozzles for shrink tubing, and wide blades for vinyl or paint.

4) Safety & Durability: Cool-down modes, overload protection, heat-resistant housings, and tough cords keep the tool reliable for years.

5) Ergonomics: Balanced weight and angled stands reduce fatigue, especially during long sessions like full-panel wraps.

Quick Buying Checklist

- Temperature range at least 50–600°C with digital control.

- Two or more airflow settings (ideally a variable dial).

- Included nozzle kit for shrinking, concentrating, and reflecting heat.

- Hands-free stand or kickstand for bench work.

- Cool-down function and thermal cut-off safety.

- Replaceable heating element and readily available parts.

Pro Tips for Better, Safer Results

- Always pre-test on offcuts to confirm temperature and distance.

- Keep moving the nozzle to avoid scorching or warping.

- Mind the distance: 3–10 cm is a common working range; closer for precision, farther for gentle heat.

- Use the right nozzle—reflectors for tubing, wide blades for wraps, reducers for solder/spot work.

- Ventilate: stripping paints/adhesives can release fumes.

- Cool down the tool on its stand before storage to extend heater life.

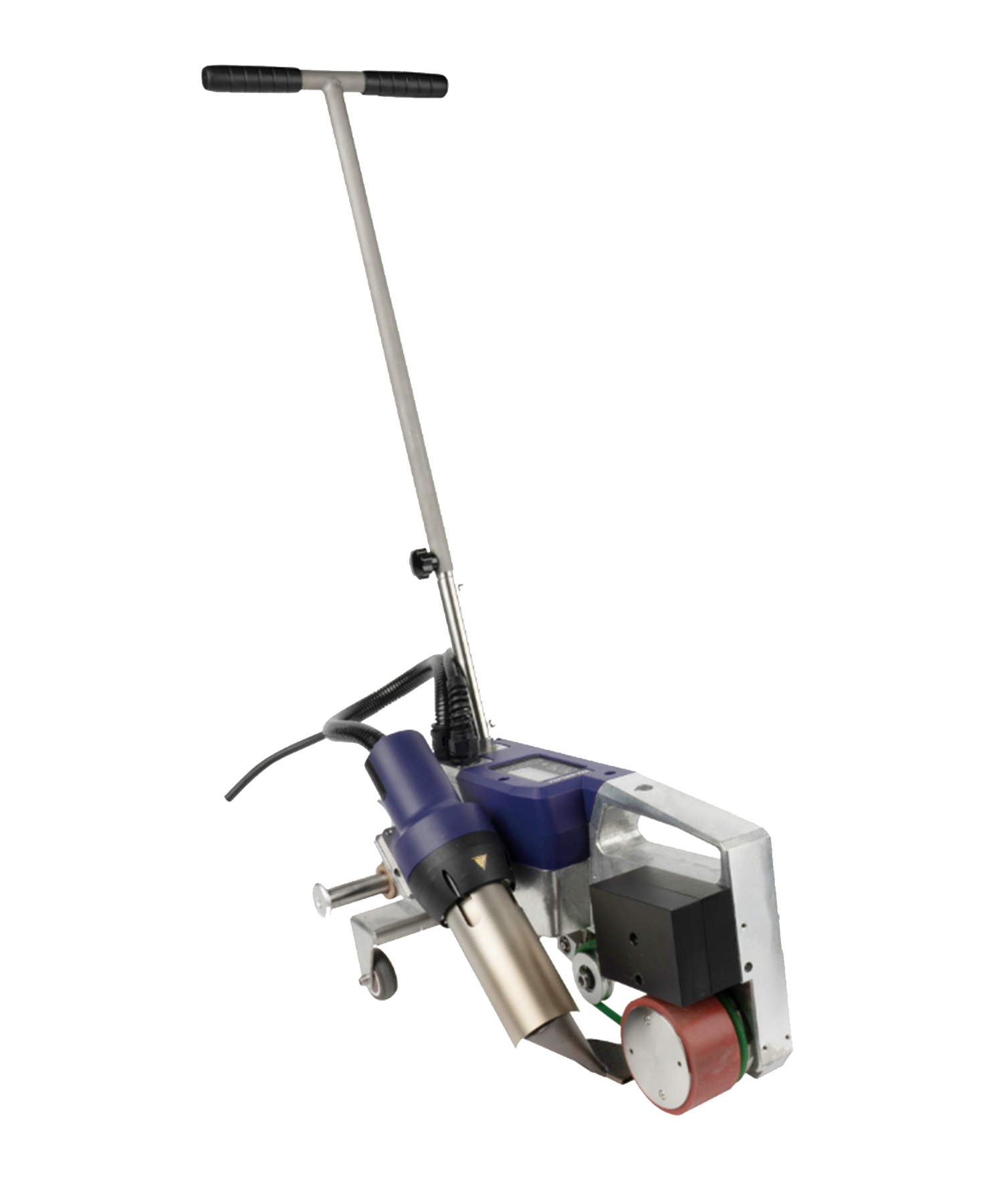

Recommended: Pro Adjustable Hot Air Gun

Wide 50–650°C range, digital display, variable airflow, and a 5-piece nozzle kit—ideal for electronics, auto wraps, and shop maintenance.

Shop Now

Cost Savings & ROI

A reliable unit reduces wasted materials (burned wrap, blistered paint, overheated plastics) and speeds up workflows. If you wrap cars, rework electronics, or strip finishes regularly, shaving even a few minutes per task adds up—often paying for the tool in weeks, not months. Add in fewer remakes, cleaner results, and happier customers, and the ROI becomes obvious.

FAQ

Q: Can I use a hot air gun instead of a torch?

A: Often yes—and it’s safer. You get focused heat without open flame, better for delicate surfaces and indoor use.

Q: What temperature for heat-shrink tubing?

A: Most shrink well between 120–200°C. Start low, increase slowly, and use a reflector nozzle for even results.

Q: How do I avoid melting plastic?

A: Use lower temps (150–300°C), keep the nozzle moving, and increase distance. Pre-test on scrap.

Find adjustable models, nozzle kits, and accessories for every workflow.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.