Meta Description: Learn how to choose the right hot air gun temperature for various DIY, crafting, and industrial projects. Includes temperature guides, safety tips, and professional recommendations.

A hot air gun is a versatile tool used in crafting, electronics repair, paint removal, shrink wrapping, and even plastic welding. However, one of the most important factors to consider when using a hot air gun is the temperature setting. Choosing the right temperature ensures you achieve the desired result without damaging your materials or causing safety hazards.

Why Temperature Matters

The temperature of a hot air gun determines how quickly it can soften, melt, or dry materials. Too low, and the process might be inefficient. Too high, and you risk burning, melting, or warping the surface. Understanding temperature ranges for different applications is crucial for both beginners and professionals.

Hot Air Gun Temperature Guide

Below is a general guide for choosing the right temperature for your project:

| Temperature Range (°C) | Applications | Tips |

|---|---|---|

| 50°C - 150°C | Drying paint, thawing frozen pipes, gentle heat shrinking | Keep the gun moving to avoid overheating |

| 150°C - 300°C | Heat-shrink tubing, vinyl wrapping, loosening adhesives | Use medium airflow for better control |

| 300°C - 500°C | Paint stripping, bending plastics, soldering | Wear gloves and work in a ventilated space |

| 500°C - 650°C | Welding plastics, removing rusted bolts | Only for experienced users, high fire risk |

Factors That Affect Temperature Choice

1. Material Type

Different materials respond differently to heat. For example, PVC softens at much lower temperatures than metal.

2. Project Purpose

For delicate electronics repair, lower temperatures are safer, while heavy-duty stripping or welding requires higher heat.

3. Airflow Control

Many hot air guns allow you to adjust airflow. Low airflow focuses heat on a small area, while high airflow spreads heat over a larger surface.

Safety Tips

- Always wear heat-resistant gloves and safety glasses.

- Never point the gun at yourself or others.

- Keep flammable materials away from the work area.

- Allow the tool to cool down completely before storage.

Professional Recommendation

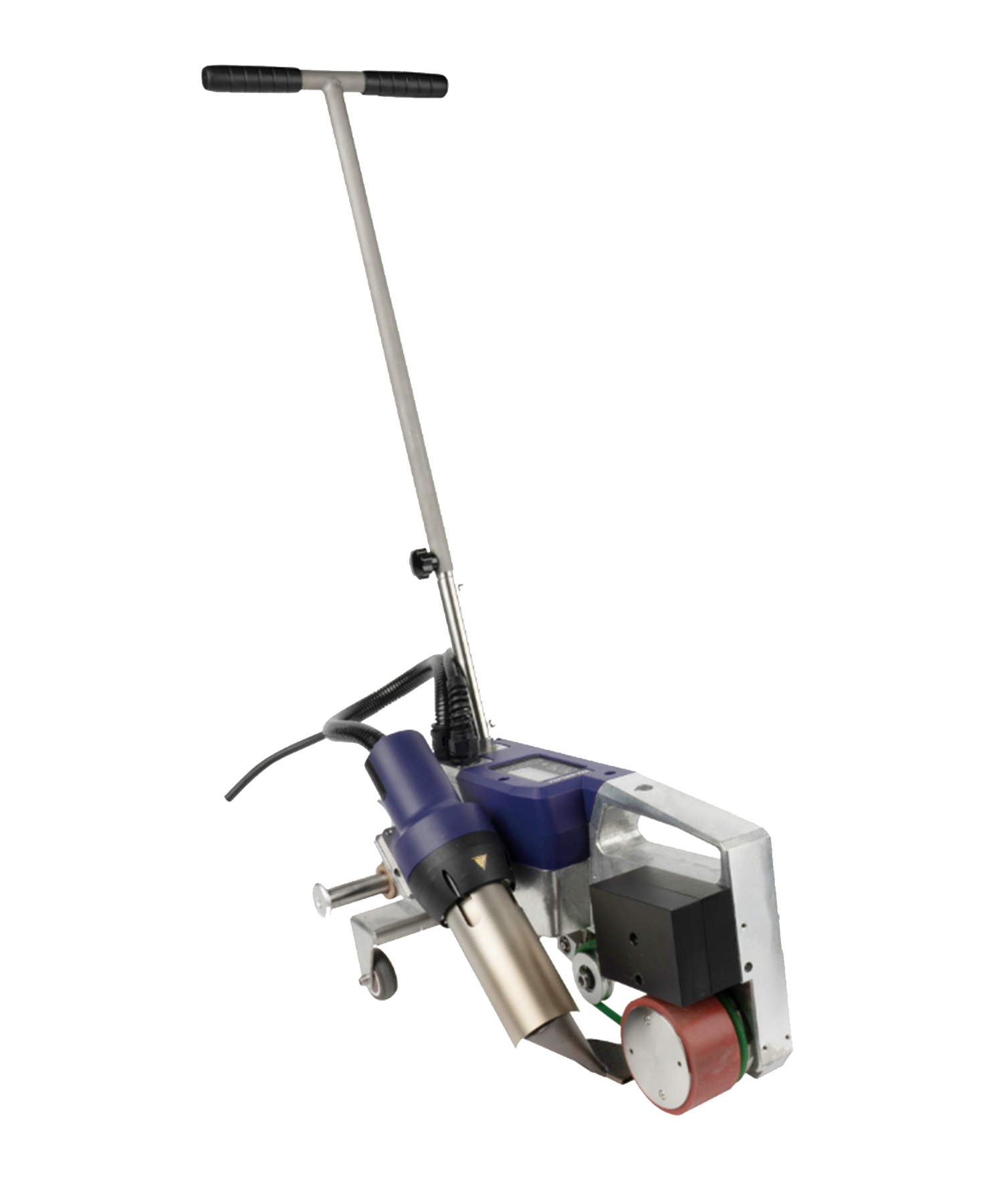

If you work on a variety of projects, invest in a hot air gun with adjustable temperature settings and multiple nozzles. This ensures you have the flexibility to handle anything from delicate shrink tubing to heavy-duty paint removal.

Recommended Product

Check out our High-Precision Adjustable Hot Air Gun – perfect for crafting, repairs, and industrial use.

Shop NowChoosing the right temperature for your hot air gun not only improves your project quality but also extends the lifespan of your materials and tools. Take your time to test different settings, and always prioritize safety.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.