In modern construction, roof welding is a critical process for ensuring building waterproofing and structural integrity. This article systematically introduces various types of equipment required for roof welding, including their functional characteristics, applicable scenarios, and operational key points, providing comprehensive equipment selection references for engineering teams.

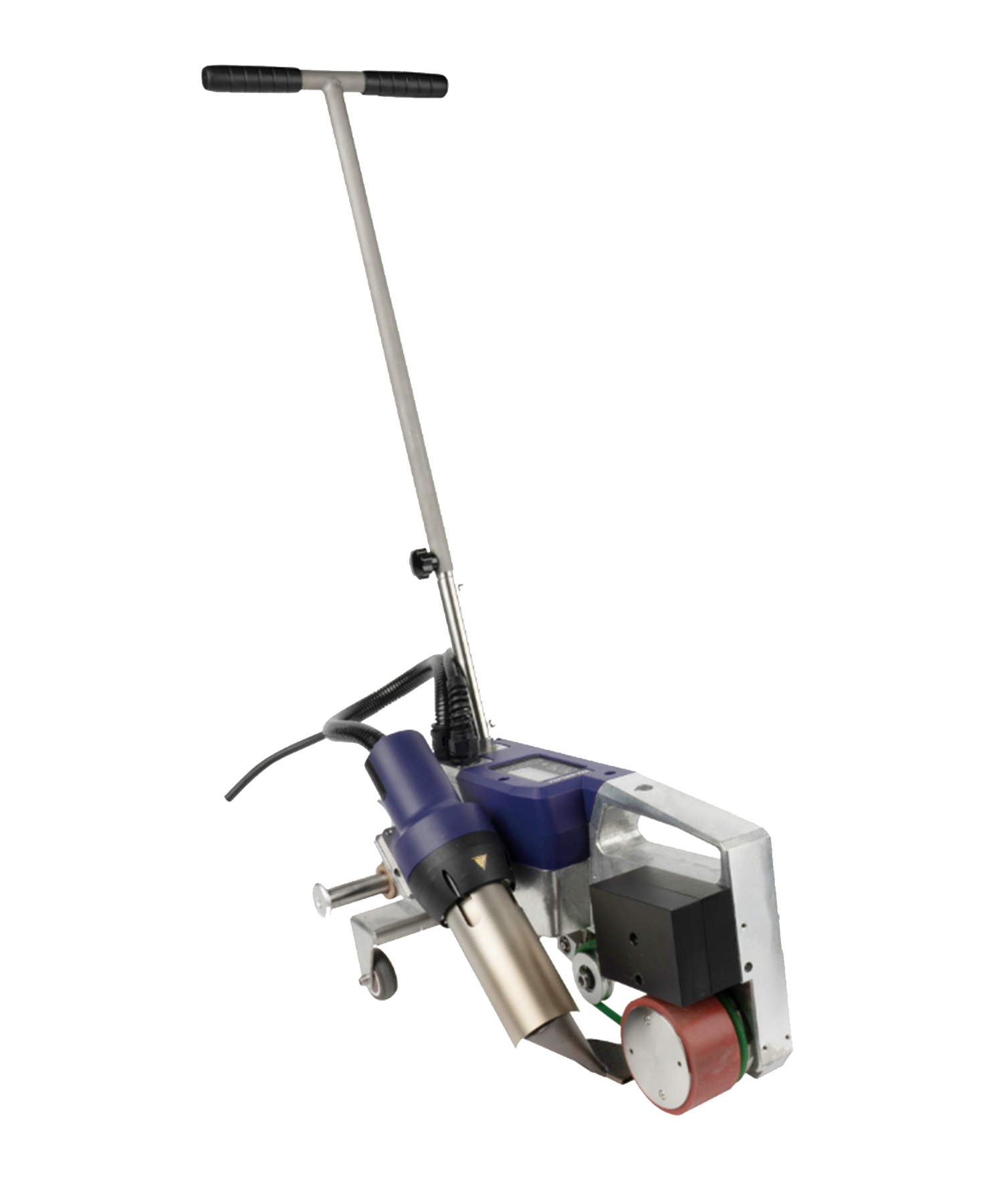

Automatic Roof Welding Machine Systems

Automatic roof welders are core equipment for large-scale roofing projects, mainly consisting of the following components:

Main Unit: Equipped with digital temperature control systems for precise welding temperature adjustment (typically 150-450°C)

Travel Mechanism: Features variable frequency drive with adjustable speed (0.5-5 meters/minute)

Hot Air System: Delivers airflow up to 200-500L/min

Technical Advantages:

Increases welding efficiency by 3-5 times compared to manual operation

Achieves seam strength exceeding 90% of base material

Maintains weld uniformity within ±2mm tolerance

Typical Applications:

Welding TPO/PVC waterproof membranes for large factory buildings

Continuous welding for airport terminal roofs

Installation of photovoltaic roof integration systems

Operational Notes:

① Conduct test welds (≥300mm length) before formal work

② Preheat substrate when ambient temperature is below 5°C

③ Match travel speed to material thickness (recommend 2m/min for 1.5mm membranes)

Manual Hot Air Welding Tools

Essential for detail work and repairs:

Hot Air Guns:

Power: 2000-3000W

Temperature range: Adjustable 50-600°C

Includes various nozzles (round/flat, etc.)

Extrusion Guns:

Suitable for materials >3mm thick

Welding rod diameter: 3-5mm

Feed speed: 0.5-3m/min

Application Scenarios:

Complex joints like pipe penetrations and gutters

Reinforcement of inside/outside corners

Localized damage repairs

Techniques:

Maintain 45° angle between gun and work surface

Control welding pressure at 0.2-0.3MPa

Ensure ≥50mm overlap width

Pressure Roller Systems

Critical auxiliary tools for weld quality:

Silicone Pressure Wheels:

Hardness: 60-80 Shore A

Operating temperature: -20°C to 150°C

Sizes: φ50-100mm

Heated Rollers with Temperature Control:

Surface temperature: 80-120°C

Adjustable pressure: 5-20kg

Key Points:

① Roll immediately after welding (<10 second interval)

② Follow "advance then press" sequence

③ Use shaped rollers (e.g., L-type) for complex areas

Power System Solutions

Tailored configurations for different environments:

Diesel Generators:

Power: 10-50kVA

Recommended brands: Yamaha/Honda

Suitable for sites without grid power

Lithium Battery Systems:

Voltage: 48V/72V

Runtime: 4-8 hours

Ideal for indoor renovation projects

Power Allocation Principles:

Dedicated circuit for automatic welders (≥32A)

Calculate peak load for multiple devices

Recommend 20% power reserve

Supporting Inspection Equipment

Complete welding systems should include:

Weld Inspection Devices:

Vacuum testing (negative pressure ≥0.03MPa)

Spark testing (15-30kV voltage)

Infrared Thermal Cameras:

Temperature resolution: 0.1°C

Detects defects like cold welds/overheating

Acceptance Standards:

Peel strength ≥50N/cm (EN 12316-1)

Air-tightness maintained for 30 minutes

Equipment Maintenance

Key measures to prolong service life:

Routine Care:

Clean welder filters weekly

Lubricate rails monthly

Quarterly cable insulation checks

Storage Conditions:

Humidity <60%

Drain water lines in winter

Disconnect batteries for long-term storage

Safety Gear

Essential PPE includes:

Heat-resistant gloves (withstands 500°C)

Respirators (organic vapor cartridges)

Anti-static workwear

Safety goggles (with side shields)

Conclusion

A complete roof welding system requires an investment of approximately ¥150,000-500,000. For enterprises with annual construction volumes exceeding 50,000m², we recommend configuring 2 automatic welders plus 10 manual tool sets. Proper use and maintenance of welding equipment can not only improve efficiency but also ensure roof systems meet 20+ year design lifespans. When purchasing, prioritize manufacturers with EN 13067 certification.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.