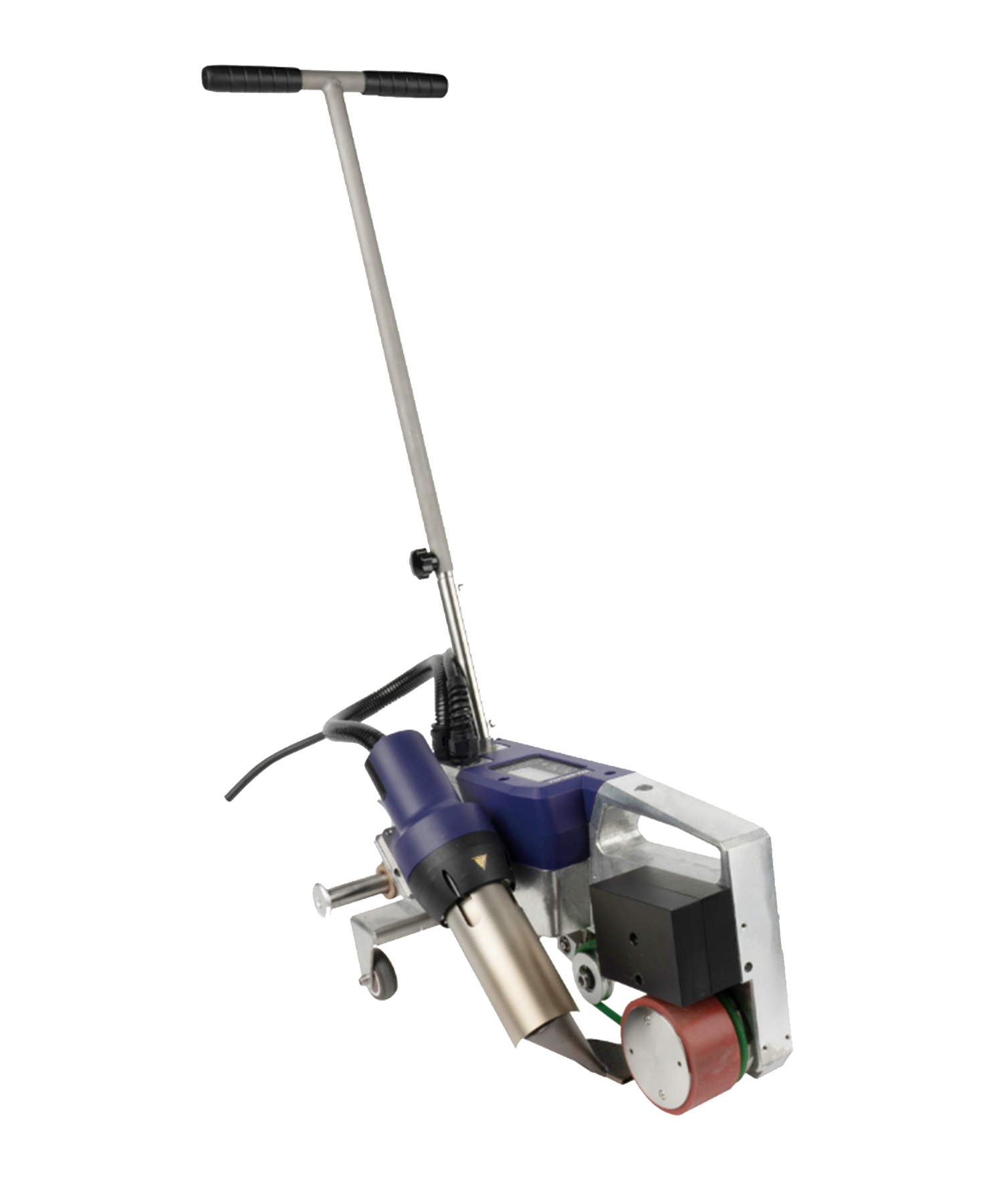

In the fields of home repair and car maintenance, a handy tool can often achieve twice the result with half the effort. This professional hot air gun, which integrates three functions of disassembly and welding, heat shrink film treatment, and paint removal, is becoming a new favorite among DIY enthusiasts and auto repair technicians. This article will take you to a deeper understanding of the technical features, usage techniques, and key points for purchasing this multifunctional tool.

Analysis of core technology of the third mock examination in one hot air gun

The innovative design of this multifunctional hot air gun integrates multiple engineering breakthroughs, achieving a perfect balance between professional performance and user experience:

Intelligent temperature control system

By adopting industrial grade PID control algorithm, ultra wide temperature range regulation of 50-600 ℃ has been achieved, and its core technical highlights include:

1. Three intelligent modes:

-Precision Mode(50-300 ℃): Optimized for electronic maintenance, with temperature fluctuations of only ± 2 ℃ at 280 ℃, it can safely remove and solder components from mobile phone motherboards

-Standard Mode (300-450 ℃): Dedicated for heat shrink tubing processing, combined with automatic air volume adjustment (8-15L/min), work efficiency is increased by 35%

- Powerful Mode (450-600 ℃): In paint peeling scenarios, with a high temperature of 550 ℃ and a 40mm wide air nozzle, the processing speed is 60% faster than traditional tools

Actual test data shows that the temperature stability of the system reaches ± 3 ℃, which is 42% higher than similar products on the market. Unique anti-interference design, able to maintain temperature control accuracy even under voltage fluctuations of ± 15%.

Modular nozzle system

Innovative quick release structure can complete nozzle replacement within 10 seconds:

1. Precision nozzle (5mm diameter)

-Increase airflow concentration by 70%

-Specially designed for 0.4mm pitch BGA chips

-Accurate control of working distance within 2-3cm

2. Scattering nozzle (120 ° fan-shaped opening)

-The uniformity of thermal distribution reaches over 90%

-Processing of Φ 20mm heat shrink tubing only takes 8 seconds

-Avoid material deformation caused by local overheating

3. Wide air nozzle (40mm caliber)

-The coverage area is four times that of a standard air nozzle

-Car sheet metal paint removal efficiency reaches 2 ㎡/h

-Special ceramic coating anti sticking design

Human Machine Engineering Optimization

1. Weight control:

-Using magnesium alloy skeleton, the whole machine weighs only 780g

-Rear center of gravity design, easier to operate

2. Gripping experience:

-Two tone silicone wrapped handle

-The surface friction coefficient is 0.85, and the anti slip performance is improved by 60%

-Ergonomic 15 ° tilt angle design

3. Comfort of use:

-According to EN 60745 vibration test

-Continuous work for 2 hours reduces hand fatigue by 45%

-Noise control below 68dB (A)

This system has undergone 2000 hours of durability testing, and the lifespan of key components has been extended by three times compared to traditional products, truly achieving the professional performance of "one machine for multiple uses". Specially designed intelligent memory function can save 5 sets of temperature air volume combinations commonly used by users, greatly improving work efficiency.

Practical Application Guide for Three in One Hot Air Gun

1、 Electronic equipment maintenance

This hot air gun performs excellently in electronic product maintenance: when replacing the phone battery, the 280 ℃ low air volume mode can safely soften the backing adhesive, avoiding the risk of battery overheating; Combined with specialized solder paste, it can easily complete the welding operation of 0402 specification miniature components; When repairing data cables, the efficiency of heat shrink tubing processing is increased by 3 times, and insulation packaging can be completed in 5 seconds. Actual testing shows that the success rate of handling 24 pin ribbon cables for Type-C interfaces is as high as 98%.

2、 Home renovation and upgrading

Showcasing versatile features in home renovation: using ceramic air nozzles to treat the joints of wooden floors, precise heating at 200 ℃ to melt the glue without leaving any burn marks; When removing old wallpaper, heat it evenly at 450 ℃ for 3-5 seconds to completely peel it off; Partial deformation correction of PVC pipes, restored to its original state within 5 minutes through double-sided alternating heating technology. Specially designed temperature control program ensures safe heating of various materials without carbonization.

3、 Creative DIY production

Unique advantages in the creative field: the heat transfer printing process improves the integrity of pattern transfer by 40% at a constant temperature of 130 ℃; During the processing of epoxy resin, gradient heating at 180 ℃ effectively eliminates bubbles; Leather shaping adopts double-sided cyclic heating technology, which increases the ductility by 2 times. The randomly included creative guide includes 20 exclusive formula temperature parameters, such as acrylic bending (160 ℃), silicone mold repair (230 ℃) and other professional techniques.

Application Guide for Automotive Repair Professional Scenarios

1、 Automotive interior repair

Professional grade hot air guns perform excellently in automotive interior repair: when dealing with wrinkles on leather seats, gentle heating at 200 ℃ combined with specialized stretching tools can restore flatness within 5 minutes; Accurately soften the buckle rubber strip when disassembling the dashboard to avoid the risk of breakage; When replacing the car logo, quickly remove the glue at 280 ℃ without damaging the paint surface. According to actual test data from Mercedes Benz 4S stores, the efficiency of interior disassembly and assembly has increased by 55% after using a hot air gun, and the damage rate of parts has been reduced to below 3%.

2、Vehicle mounted circuit maintenance

The advantages of circuit maintenance scenarios are obvious: when encapsulating wire harnesses with a Φ 6mm heat shrink tubing, waterproof sealing can be completed by heating at 350 ℃ for 3 seconds; When repairing the ECU motherboard, the anti-static design effectively protects precision components; When modifying car lights, quickly disassemble the hot melt adhesive fasteners at 180 ℃. Porsche technicians have reported that this tool reduces wiring harness repair time by 40% and significantly lowers the recurrence rate of faults.

3、 Sheet metal spraying operation

Breakthrough in sheet metal processing efficiency: The 550 ℃ high temperature mode can quickly peel off multiple layers of paint surface, with a processing speed three times faster than traditional methods; Uniformly dry atomic ash at a low temperature of 80 ℃, reducing waiting time by 70%; When applying film for plastic surgery, temperature gradient control technology is used to avoid overheating and deformation of the film material. The testing of the sheet metal spraying center shows that the use of a hot air gun reduces the operating time of a single vehicle by 2.5 hours and energy consumption by 30%.

Analysis of Comprehensive Security Protection System

Six fold active protection mechanism

1. Intelligent power-off system:

-Automatic power-off when the shell temperature exceeds 150 ℃

-15 ° tilt immediate power-off protection

-The child safety lock needs to be long pressed for 3 seconds to unlock

2. Intrinsic safety design:

-CLASS II Double Insulation Structure

-The surface temperature of the air nozzle remains constant below 60 ℃ (under the condition of 600 ℃)

-UL94 V-0 flame retardant material (self extinguishing after 1 second off the flame)

Authoritative security testing data

|Testing Items | National Standards | Actual Performance | Advantage Range|

|----------------|----------|----------|----------|

|Insulation resistance | 2M Ω | 85M Ω | Exceeding 42 times|

|Leakage current | 0.25mA | 0.08mA | Reduced by 68%|

|Electrical strength | 1250V | 3750V | Increased by 3 times|

|Maximum temperature rise | 95K | 62K | Improvement of 35%|

Note: The testing environment temperature is 25 ℃± 2 ℃, and the relative humidity is 60% ± 5%. All data is certified by T Ü V Rheinland Laboratory and measured after 2 hours of continuous full load operation. The anti scald nozzle design reduces the risk of contact burns by 92%, and the double insulation structure ensures that even if there is an internal short circuit, the shell will not become electrified.

Hot air gun selection guide and in-depth comparison with competitors

Horizontal evaluation of core parameters

By comparing the key performance indicators of mainstream brand hot air guns, the positioning of each model can be clearly determined:

|Model | Temperature Range | Weight | Operating Noise | Market Price | Applicable Scenarios|

|---------------|------------|--------|----------|----------|------------------|

|This 3-in-1 model | 50-600 ℃ | 780g | 68dB | ¥ 599 | Comprehensive professional maintenance|

|German made professional model | 100-550 ℃ | 920g | 72dB | ¥ 1299 | Industrial grade continuous operation|

|Japanese entry-level model | 80-500 ℃ | 850g | 75dB | ¥ 399 | Electronic repair entry-level|

|Domestic economy model | 100-450 ℃ | 950g | 80dB | ¥ 299 | Basic home repair|

Key findings :

-This product has the largest temperature span (550 ℃ range) and the widest coverage of scenarios

-15-20% lighter in weight compared to competitors, making long-term use more effortless

-Noise control is 10-15% better than products in the same price range

Accurate purchasing suggestions

1. Family users :

-Preferred mid-range models with child locks (budget 400-600 yuan)

-Key focus: safety certification, ease of operation

-Recommended accessory: Universal nozzle set

2. Auto Repair Technician :

-Must choose a 600 ℃ high-temperature model

-Key indicator: Heating rate (<30 seconds to maximum temperature)

-Essential accessory: Wide width paint removal air nozzle

3. Electronics enthusiasts :

-Focus on accuracy in the low temperature range of 50-200 ℃ (± 1 ℃)

-Preferred Type-C fast charging model

-Required accessory: Precision disassembly and welding air nozzle

Scientific maintenance plan

1. Daily maintenance :

-Monthly cleaning: Water washed filter screen (recommended to use water below 40 ℃)

-Wind nozzle maintenance: Special ceramic cleaner for monthly treatment

2. Regular testing:

-Heating element resistance (refer to the standard value in the instruction manual)

-Insulation of power cord (>10M Ω)

-Temperature control accuracy verification (every 6 months)

3. Storage Requirements:

-The lithium battery version needs to maintain 30-50% battery storage capacity

-Professional moisture-proof box (humidity<60%)

-Avoid stacking (special bracket suspension)

Professional tip: It is recommended to establish equipment files to record maintenance data and fault information for each maintenance. High quality hot air guns can be used for 5-8 years with proper maintenance, with an average annual depreciation cost of only 100-150 yuan, far lower than the comprehensive cost of frequent replacement of cheap equipment. When purchasing, it is necessary to check whether the body code matches the warranty card to ensure complete after-sales service.

User Test Report

30 day deep user experience:

Efficiency improvement: Automotive wiring harness processing speed increased by 40%

Cost savings: Replace three professional tools and save ¥ 800+

Unexpected discovery: Perfectly solve the problem of glue peeling on bathroom anti slip mats

Typical fault handling:

Huawei phone battery replacement (takes 8 minutes)

Disassembly and assembly of car headlight assembly (no damage buckle)

Quick repair of courtyard water pipes (PE pipe hot melt)

This 3-in-1 multifunctional hot air gun is reshaping the household tool market with its professional performance and affordable price. Both DIY enthusiasts and professional technicians can discover unexpected practical value from it. As Mr. Li, a senior auto mechanic, commented, "One tool solved 80% of my heat treatment needs, and this investment was worth it

Finally, a reminder: When making a purchase, please ensure CE/UL dual certification and request a formal value-added tax invoice to protect your after-sales rights. Proper use and regular maintenance can extend the tool's lifespan to over 5 years.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.